Reduced Order Modeling: Applications and Techniques for Creating ROMs

From the series: Reduced Order Modeling with MATLAB Video Series

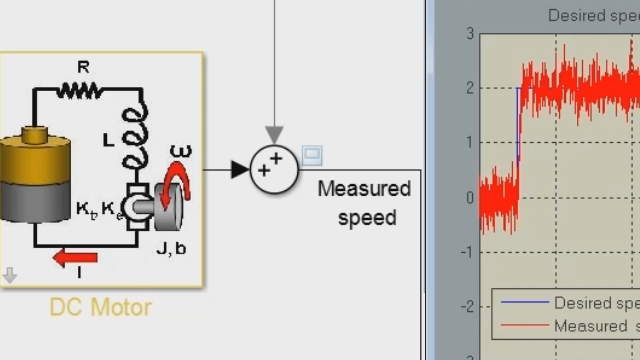

Reduced order modeling (ROM) is a technique for simplifying a high-fidelity mathematical model by reducing its computational complexity while preserving the dominant behavior of the complex model.

One common application of reduced order modeling enables simulation of third-party FEA/FEM/CFD models in Simulink® including hardware-in-the-loop testing. Other ROM applications include virtual sensor modeling, control design, and digital twins. This overview also highlights different techniques for creating reduced order models with MATLAB® and Simulink such as data-driven modeling (including static and dynamic models), model-based ROMs, linearization-based methods, and physics-based reduction.

Published: 4 Dec 2023