Nonlinear MPC Deployment to Speedgoat Hardware for Real-Time Testing | Understanding Model Predictive Control, Part 9

From the series: Understanding Model Predictive Control

Timo Straessle, Speedgoat

Melda Ulusoy, MathWorks

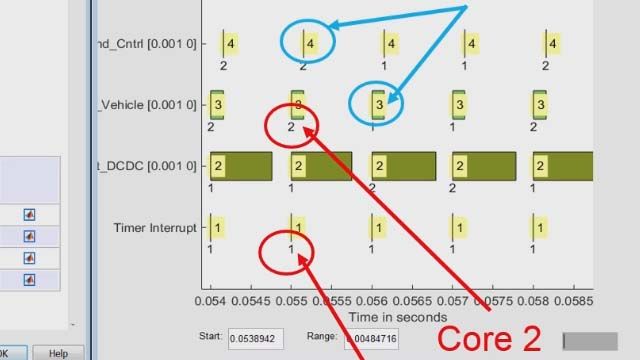

Learn how to generate code from a nonlinear mpc algorithm for an automated driving application and deploy the generated code to Speedgoat® hardware for real-time testing. This video uses the FORCES PRO-based nonlinear MPC algorithm developed in the previous video and shows how to partition the model into multiple components for deployment to Speedgoat hardware.

Published: 5 Aug 2022