Lab-in-a-Box Approach for Teaching Control: Bridging the Gap Between Theory and Practice

Dr. James Pickering, Aston University

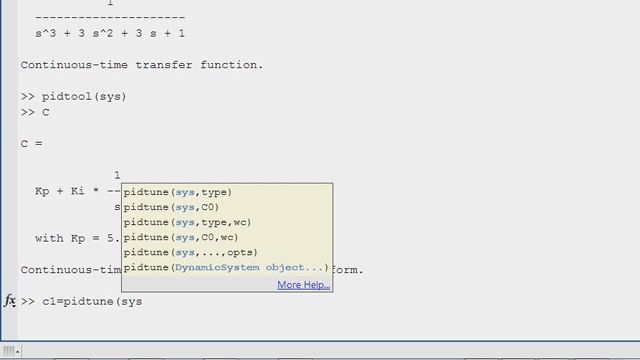

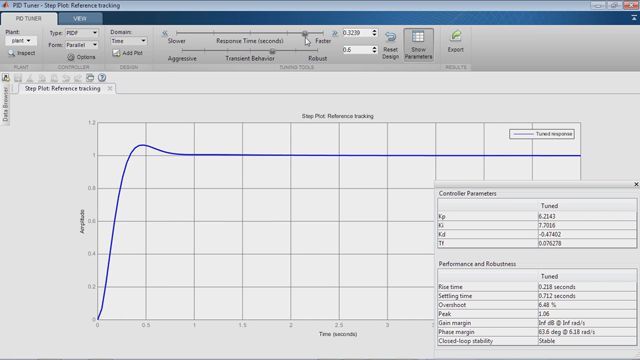

Discover how Aston University’s Future Vehicle Technologies MSc course teaches AV control algorithm design. Utilizing a “lab-in-a-box” approach, students master control engineering fundamentals through Model-Based Design with MATLAB® and Simulink®. They develop real-time systems, focusing on DC motor control, including speed control, temperature control, and obstacle avoidance. Students report positively on the transferrable skills that let them apply their learnings from “lab-in-a-box” to the Roboworks Rosbot Plus TX platform.

Published: 16 Oct 2024