Condition monitoring and anomaly detection: Workflow, techniques, and case study

Overview

Many industries are looking to AI to increase efficiency, gain new insights, and improve product quality by automating production process monitoring and optimization of maintenance scheduling. Even when production lines are equipped with sensors to collect valuable data, at times engineering teams lack the data science skills required to implement AI models for predictive maintenance and advanced process analytics.

MAN Energy Solutions SE, a German multinational, that produces diesel engines and turbomachinery for marine and stationary applications worked with MathWorks Consulting on a proof of concept using machine learning techniques to detect error conditions in gas turbines.

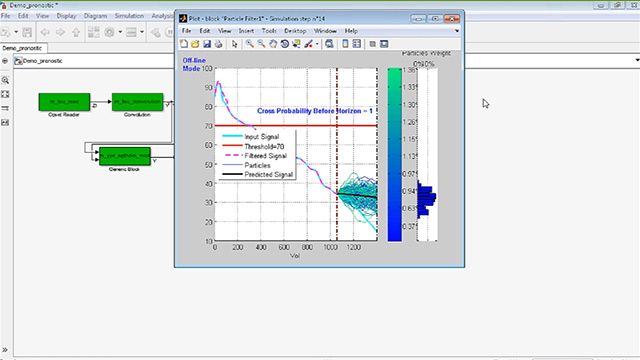

In this webinar we will demonstrate how the team aims to automate the time-consuming process of visualizing and manually evaluating measured sensor data, to determine error conditions at an early stage. Furthermore, MathWorks engineers are going to walk the audience through the predictive maintenance workflow and showcase different techniques for anomaly detection.

Highlights

- Real-world case study

- Preprocessing sensor data

- Identifying condition indicators

- Using machine learning for anomaly detection

- Operationalizing algorithms on embedded systems and IT/OT systems

About the Presenters

Yvonne Blum is a Senior Consultant at MathWorks, focusing on Data Science. She has an academic background in theoretical physics and biomechanics.

Sebastian Bomberg is an Application Engineer at MathWorks and supports customers in implementing Artificial Intelligence projects such as for forecasting, predictive maintenance and IoT. He is a subject matter expert in machine and deep learning, as well as Big Data algorithms and cloud computing. Sebastian Bomberg holds a Dipl.-Ing. degree in mechanical engineering from Technische Universität München.

Recorded: 26 Oct 2022