Interpreting Torque in the Angle-Based Rotational Domain

This example describes how to interpret torques in a Simscape™angle-based rotational network. It outlines the key concepts for understanding the signs of logged torques. It examines rotational spring systems driven by torque sources at different ends, as well as a rotational system of inertias, to illustrate the torque behavior.

Governing Principles for Torque Behavior

The angle-based rotational domain uses two key principles to define torque behavior:

Principle 1: Parts Align with the Axis Positive Direction

The Simulink® canvas shows block connectivity rather than part orientation. Consider the Simulink canvas as a schematic view. While you can rotate blocks on the canvas for better visualization, it is important to keep the positive direction of all blocks aligned for intuitive interpretation of simulated torques.

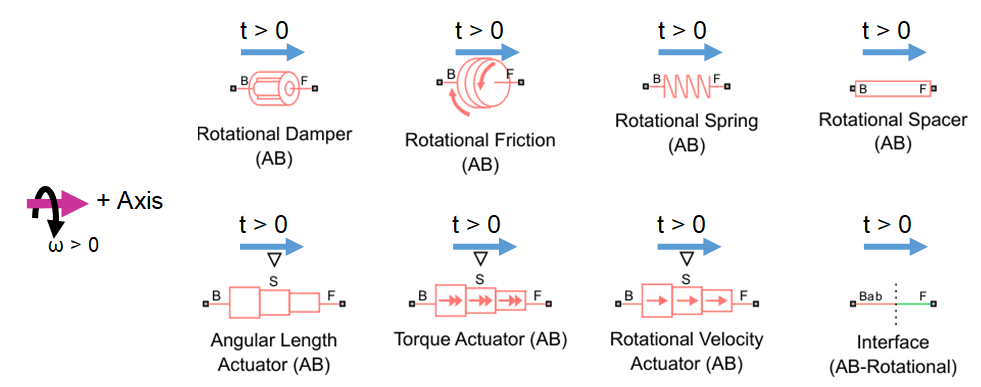

The axis of each rotational network has a positive direction, which you can set to point left, right, up, or down on the canvas. Two-port blocks have an internal positive direction that points from port B to port F. When you add the two-port block to the network and orient it, you establish the axis's positive direction. Ensure that the internal positive direction of all two-port blocks aligns with the network's positive direction for intuitive torque interpretation.

In this image, all two-port blocks are aligned with port B on the left and port F on the right. This arrangement means the positive direction for each block points from port B to port F, which is from left to right. Consequently, the positive axis direction is also to the right, as indicated by the arrow labeled '+Axis'.

The Interpreting Torque in the Angle-Based Rotational Domain example provides more information on configuring the axis positive direction.

Principle 2: Torque Flows Through Rotational Networks

Torque flows through rotational networks. In the schematic view, torque flowing into a node represents torque acting on the node from the rest of the system. Conversely, torque flowing out of a node represents torque exerted by the node on the rest of system. The sign of the torque value indicates if the torque acts in the positive or negative direction.

Summary: In the schematic view, an arrow tail indicates that a node provides torque. An arrowhead indicates that a node receives torque.

At each node in the schematic, the sum of torques flowing into the node equals the sum of torques flowing out of the node. This balanced flow of torques in the schematic corresponds to balanced torques in the physical world.

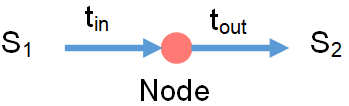

In this image, torque t_in flows from part of the system S1 into the node, and torque t_out flows from the node to another part of the system S2. This flow configuration indicates that system S1 applies torque t_in on the node, and the node applies torque t_out on the system S2. A positive value of t_in means that S1 drives the node in the positive rotational direction, while a negative value of t_in means that S2 drives the node in the negative rotational direction.

Since every torque has an equal and opposite reaction torque, you can always flip the arrow directions and scalar signs to represent equivalent torque flow behavior. The torque flow schematics in this example have flipped the arrow directions when necessary so that the arrows in the torque flow schematics correspond to positive scalar torques.

In the angle-based rotational domain, the positive rotation direction follows a right-hand rule around the axis. The Interpreting Torque in the Angle-Based Rotational Domain example provides more information on configuring the axis positive direction.

Guidelines for Applying and Interpreting Torque

The governing principles lead to the following concepts that you can apply while setting up models and interpreting their behavior.

1. t > 0 in two-port element and actuator blocks means the B node drives the F node in the positive rotational direction

In two-port element and actuator blocks, the B and F ports typically represent different points in the system. In two-port element and actuator blocks, a positive logged torque (t > 0) means that the B node drives the F node in the positive rotational direction. The logged torque t represents the internal torque acting from port B on port F. A positive internal torque indicates that port B drives port F in the positive direction, while a negative torque indicates that port B drives port F in the negative direction. Although Simscape logs only the internal torque from port B to port F, Newton's Third Law dictates that port F simultaneously exerts an equal and opposite torque on port B.

In a torque flow schematic, the internal torque of a two-port block is depicted as an arrow pointing from port B to port F (when port B applies a positive torque on port F) or from port F to port B (when port B applies a negative torque on port F). This image shows torque flowing from port B to port F in the two-port element and actuator blocks.

Simscape does not track information about whether t > 0 corresponds to an element being in a state of compression or tension. For helical torsional springs, t > 0 may correspond to the coils being twisted to either increase (state of compression) or decrease (state of tension) in diameter, depending on if the spring has a left-hand or right-hand winding.

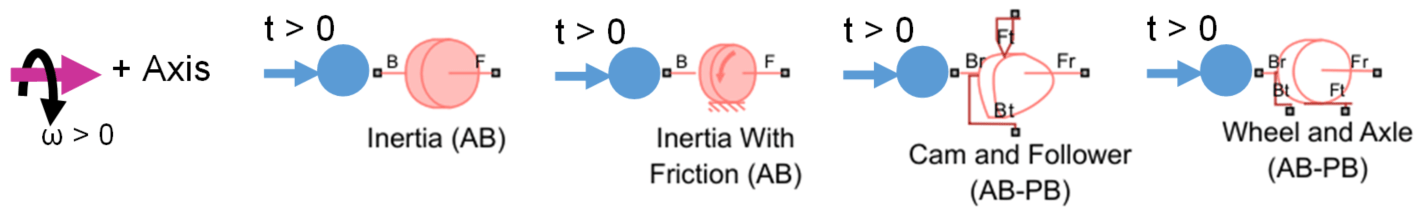

2. t > 0 in inertia and mechanism blocks means the rotational system tries to accelerate the block in the positive rotational direction

Inertia and mechanism blocks can optionally display one or two rotational ports. The two rotational ports are primarily for graphical purposes, allowing a straight line to connect the rotational network on the canvas. These two graphical rotational ports are functionally the same node. Any blocks graphically connected to port B or port F are functionally connected to each other at a single common node.

In Inertia and Mechanism blocks, a positive logged torque (t > 0) indicates that the rotational system is attempting to accelerate the block in the positive rotational direction. The logged torque t in the Inertia block represents the torque absorbed by the inertia. When torque flows into the inertia, it accelerates in the positive direction, . Conversely, a negative logged torque (t < 0) indicates torque flowing out of the inertia, meaning the rotational system accelerates the inertia in the negative direction. Inertias both absorb and release torque.

Similarly, for the Cam and Follower and Wheel and Axle mechanisms, the logged torque t represents torque flowing into the mechanism from neighboring rotational system blocks. Torque flowing into the mechanism acts to accelerate it in the positive rotational direction. Conversely, a negative logged torque t indicates that torque is flowing out of the mechanism due to the rotational system acting to accelerating it in the negative rotational direction. These mechanisms add and remove torque from the rotational network as they exchange power with the translational network.

This image shows torque flowing into the inertia and mechanism blocks. The blue circles represent the block's ability to absorb or release torque.

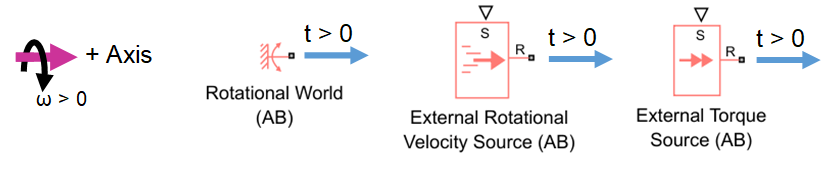

3. t > 0 in 1-port sources and the World block means the block applies torque on the system in the positive direction

The logged torque t in a source or constraint represents the torque flowing out of the block and into the rest of the system. When torque flows out of a source block, such as an External Torque Source, it indicates that the source is acting to accelerate the attached system node in the positive direction. Conversely, torque flowing out of a World block indicates that the block is acting to prevent the attached system node from accelerating in the negative direction. The accompanying image illustrates positive torque flowing out of both the World and source blocks.

Torque in Springs Example

Open the model InterpretingTorqueSprings.

open_system('InterpretingTorqueSprings');

This model considers four different systems of a rotational spring driven by a torque source. It includes a Simscape schematic labeled with torque flow arrows and a physical view for each system. In the torque flow schematics, the magnitude of the torque flow is always positive. According to Principle 2, the node at the tail of the torque flow arrow exerts torque while the node at the arrowhead receives torque.

In all systems, the positive axis direction points to the right. In the physical views, the spring endpoints represented by red circles, each have an angle of 0 degrees when the dashed line from the axis to the spring endpoint points vertically upwards, aligning with the network's direction. The node attached to the wall has an angle of 0 degrees. The node connected to the torque source starts with an initial angle of 10 degrees, as specified by the spring's Angular length parameter. The spring's angular length is defined as , where is the angle at the spring's F node and is the angle at the spring's B node.

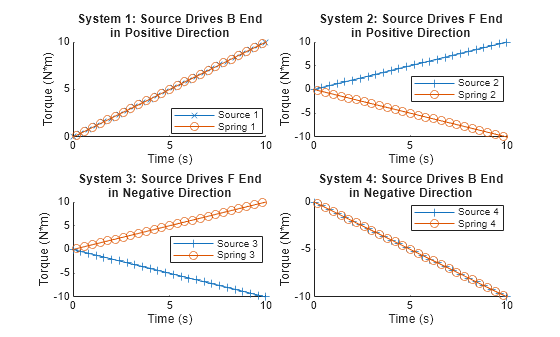

Simulate the system and plot the logged torques in the sources and springs.

open_system('InterpretingTorqueSprings'); sim('InterpretingTorqueSprings'); InterpretingTorqueSpringsPlot;

In System 1, a torque source applies a positive torque to the spring's B node, as shown by the Ramp 1 block displaying '1 N*m/s' and the blue torque flow arrow emitting from the torque source. Simscape logs this positive torque as a positive value for the source's t variable. This positive torque drives the spring's B node in the positive rotational direction. Consequently, the spring's B node applies a positive internal torque on the spring's F node, attempting to drive it in the same direction. A blue torque flow arrow from node B to node F indicates this interaction. Simscape logs this internal torque as a positive value for the spring's variable t. As the B node moves positively and the F node remains stationary, the spring's angular length, , decreases from its initial 10 degrees, indicating that the B node moves closer to the F node.

In System 2, the torque source instead applies a positive torque to the spring's F node. Similar to System 1, torque flows out of Torque Source 2, and Simscape logs a positive value for t. The spring's F node then applies a positive internal torque on the B node, attempting to drive it positively. A blue torque flow arrow from node F to node B illustrates this interaction. As the F node moves positively and the B node remains stationary, the spring's angular length, , increases from its initial 10 degrees.

In System 3, the torque source applies a negative torque to the spring's F node, drives the spring's F node in the negative direction. This interaction is indicated by a blue torque flow arrow pointing into Torque Source 3. The spring's F node then applies a negative torque to the spring's B node. The B node reacts by applying a positive torque back to the F node. The torque flow arrow from node B to node F indicates that the B node applies a positive torque on the F node. As the F node moves negatively and the B node is stationary, the spring's angular length, , decreases from its initial 10 degrees.

In System 4, the torque source applies a negative torque to the spring's B node, drives the B node in the negative direction. This interaction is represented by a blue torque flow arrow pointing into Torque Source 4. The spring's B node, in turn, applies a negative torque on the spring's F node. Therefore, the torque flow arrow for the spring points from the spring's F node to the spring's B node. As a reaction, the spring's B node applies a negative torque on the spring's F node, so Simscape logs a negative value of t for the spring. As the B node moves negatively and the F node is stationary, the spring's angular length, , increases from its initial 10 degrees.

Torque in Inertias Example

Open the model InterpretingTorqueInertias.

open_system('InterpretingTorqueInertias');

In this model, the torque source drives the Inertia 1 block, which has an inertia of 1 kg*m^2. Inertia 1 is connected to a spring. The other end of the spring is connected to the Inertia 2 block, which has a larger inertia of 10 kg*m^2. The positive axis direction in this system points to the right. Initially, both inertias are at rest, and the spring is undeformed. The Torque source starts at 0 N*m, and ramps up at a rate of 1 N*m/s.

Simulate the system and plot the logged torques.

sim('InterpretingTorqueInertias');

InterpretingTorqueInertiasPlot;

The Torque Source applies torque to Inertia 1 in the positive direction, as indicated by the torque flow arrow pointing from the Torque Source to Inertia 1 in the schematic. Inertia 1 absorbs torque when it accelerates in the positive direction and releases torque when it accelerates in the negative direction. Simscape logs the torque in Inertia 1 as positive when it absorbs torque (accelerates in the positive direction) and negative when it releases torque (accelerates in the negative direction). Any torque not absorbed by Inertia 1 is transferred to the Spring. Inertia 2 absorbs all the torque that flows through the spring because it is the only block connected to the F node of the Spring.

During most of the simulation, the acceleration of both inertias is positive, indicating that they accelerate in the positive direction. The sum of torque absorbed by Inertia 1 and Inertia 2 always equals the torque provided by the Torque Source, which is consistent with balanced torque flow.