T-Junction (TL)

Libraries:

Simscape /

Fluids /

Thermal Liquid /

Pipes & Fittings

Description

The T-Junction (TL) block represents a three-way pipe

junction with a branch line at port C connected at a 90° angle to

the main pipe line, between ports A and B. You

can specify a custom junction or a junction that uses a Rennels correlation or Crane

correlation loss coefficient. When Loss coefficient model is set to

Custom, you can specify the loss coefficients of each

pipe segment for converging and diverging flows.

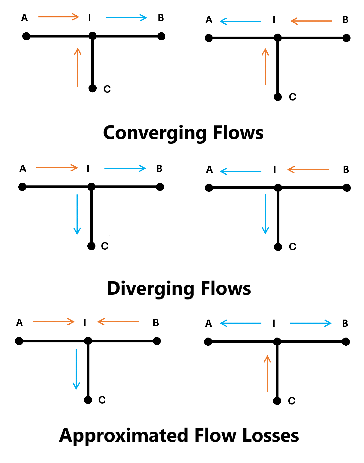

Flow Direction

When the Loss coefficient model parameter is Crane

correlation, Rennels correlation, or

Custom, the block determines each loss coefficient

based on the flow configuration. The flow is converging when

the flow through port C merges into the main flow. The flow is

diverging when the branch flow splits from the main flow.

The flow direction between A and I, the

point where the branch meets the main, and B and

I must be consistent for all loss coefficients to be

applied. If they are not, as shown in the last two diagrams in the figure below, the

losses in the junction are approximated with the main branch loss coefficient for

converging or diverging flows.

The block uses mode charts to determine each loss coefficient for a given flow configuration. This table describes the conditions and coefficients for each operational mode.

| Flow Scenario | ṁA | ṁB | ṁC | KA | KB | KC |

|---|---|---|---|---|---|---|

| Stagnant | – | – | – | 1 or last valid value | 1 or last valid value | 1 or last valid value |

| Diverging from node A | >ṁthresh | <-ṁthresh | <-ṁthresh | 0 | Kmain,div | Kside,div |

| Diverging from node B | <-ṁthresh | >ṁthresh | <-ṁthresh | Kmain,div | 0 | Kside,div |

| Converging to node A | <-ṁthresh | >ṁthresh | >ṁthresh | 0 | Kmain,conv | Kside,conv |

| Converging to node B | >ṁthresh | <-ṁthresh | >ṁthresh | Kmain,conv | 0 | Kside,conv |

Converging to node C (branch) when the Loss

coefficient model parameter is Crane

correlation or

Custom | >ṁthresh | >ṁthresh | <-ṁthresh | (Kmain,conv + Kside,conv)/2 | (Kmain,conv + Kside,conv)/2 | 0 |

Diverging from node C (branch) when the Loss

coefficient model parameter is Crane

correlation or

Custom | <-ṁthresh | <-ṁthresh | >ṁthresh | (Kmain,div + Kside,div)/2 | (Kmain,div + Kside,div)/2 | 0 |

When the Loss coefficient model parameter Rennels

correlation, the values for converging to node C (branch) and

diverging from node C (branch) are calculated directly.

The flow is stagnant when the mass flow rate conditions do not match any defined flow scenario. Stagnant flow is permitted at the start of the simulation, but the block does not revert to stagnant flow after it has achieved another mode. The mass flow rate threshold, which is the point at which the flow in the pipe begins to reverse direction, is

where:

Rec is the Critical Reynolds number, beyond which the transitional flow regime begins.

ν is the fluid viscosity.

is the average fluid density.

Amin is the smallest cross-sectional area in the pipe junction.

Crane Correlation Coefficient Model

When you set the Loss coefficient model parameter to

Crane correlation, the pipe loss coefficients,

Kmain and

Kside, and the pipe friction

factor, fT, are calculated according to

Crane [1] :

In contrast to the custom junction type, the standard junction loss coefficient is the same for both converging and diverging flows. KA, KB, and KC are then calculated in the same manner as custom junctions.

| Nominal size (mm) | 5 | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 72.5 | 100 | 125 | 150 | 225 | 350 | 609.5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Friction factor, fT | .035 | .029 | .027 | .025 | .023 | .022 | .021 | .019 | .018 | .017 | .016 | .015 | .014 | .013 | .012 |

Rennels Correlation Coefficient Model

When you set the Loss coefficient model parameter to

Rennels correlation, the block calculates the pipe

loss coefficients according to [2].

The main branch diverging loss coefficient is

where:

is the mass flow rate at the inflow of the main branch.

is the mass flow rate at the outflow of the main branch.

The value of Kmain,div saturates when is equal to the value of the Minimum valid flow ratio for coefficient calculation parameter.

The side branch diverging loss coefficient is

where

is the mass flow rate at the outflow of the side branch.

d1 is the diameter of the main branch.

d3 is the diameter of the side branch.

r is the value of the Junction radius of curvature parameter.

The value of Kside,div saturates when is equal to the value of the Minimum valid flow ratio for coefficient calculation parameter.

The main branch converging loss coefficient is

where

The value of Kmain,conv saturates when is equal to the value of the Minimum valid flow ratio for coefficient calculation parameter.

The side branch converging loss coefficient is

where:

The value of Kside,conv saturates when is equal to the value of the Minimum valid flow ratio for coefficient calculation parameter.

The loss coefficient when the flow is converging to the side branch is

where d is the diameter of the side branch. The value of Kconv to side saturates when is equal to the value of the Minimum valid flow ratio for coefficient calculation parameter.

The loss coefficient when the flow is diverging from the side branch is

The value of Kdiv from side saturates when is equal to the value of the Minimum valid flow ratio for coefficient calculation parameter.

Custom T-Junction

When you set the Loss coefficient model parameter to

Custom, the block calculates the pipe loss

coefficient at each port, K, based on the user-defined loss

parameters for converging and diverging flow and mass flow rate at each port. You

must specify Kmain,conv,

Kmain,div,

Kside,conv, and

Kside,div as the Main

branch converging loss coefficient, Main branch diverging

loss coefficient, Side branch converging loss

coefficient, and Side branch diverging loss

coefficient parameters, respectively.

Constant Coefficients T-Junction

When you set the Loss coefficient model parameter to

Constant Coefficients, the block models the junction

as a composite component of three Local Resistance

(TL) blocks joined at a center node. When the block uses this

setting, it does not use mode charts. Use this option if your model operates at

nominal conditions and does not require high fidelity.

Mass and Momentum Balance

The block conserves mass in the junction such that

The block calculates the flow through the pipe junction using the momentum conservation equations between ports A, B, and C:

where I represents the fluid inertia, and

Amain is the Main branch area (A-B) parameter and Aside is the Side branch area (A-C, B-C) parameter.

Energy Balance

The block balances energy such that

where:

ϕA is the energy flow rate at port A.

ϕB is the energy flow rate at port B.

ϕC is the energy flow rate at port C.

Variables

To set the priority and initial target values for the block variables prior to simulation, use the Initial Targets section in the block dialog box or Property Inspector. For more information, see Set Priority and Initial Target for Block Variables.

Nominal values provide a way to specify the expected magnitude of a variable in a model. Using system scaling based on nominal values increases the simulation robustness. Nominal values can come from different sources, one of which is the Nominal Values section in the block dialog box or Property Inspector. For more information, see Modify Nominal Values for a Block Variable.

Examples

Ports

Conserving

Parameters

References

[1] Crane Co. Flow of Fluids Through Valves, Fittings, and Pipe TP-410. Crane Co., 1981.

[2] Rennels, D. C., & Hudson, H. M. Pipe flow: A practical and comprehensive guide. Hoboken, N.J: John Wiley & Sons., 2012.