Limited-Slip Differential

Reduce velocity difference between two connected shafts

Libraries:

Simscape /

Driveline /

Gears

Description

The Limited-Slip Differential block represents a limited-slip differential (LSD), which is a gear assembly that limits the velocity difference between two connected shafts. The block models the LSD mechanism as a structural component that combines a differential and a clutch.

The differential component in the LSD block is an open differential. An open differential is a gear mechanism that allows two driven shafts to spin at different speeds. In an automobile, a differential allows the inner wheels to spin more slowly than the outer wheels when the vehicle is cornering. A vehicle that has wheel shafts connected by an open differential can get stuck when one of the wheels slips and spins freely due to traction loss. This vehicle stops moving because the driveshaft supplies less power to the wheel with traction than it supplies to the spinning wheel.

In the same scenario, a vehicle that has an LSD is less likely to get stuck because it contains a clutch assembly that can transmit power to the wheel that retains traction. The clutch component in the LSD block is a friction clutch that has two sets of flat friction plates. The clutch engages when applied pressure exceeds the engagement threshold pressure. In an LSD, a spring preload that separates the sun gears presses the plates in both sets together. When the shafts experience a traction differential, the planet pinion gears exert an additional force in the direction of the high-traction shaft. If the additional pressure exceeds the engagement threshold, the clutch assembly engages. The engagement allows the driveshaft to transmit more power to the slower-spinning high-traction wheel. The additional power reduces the difference in velocity of the two shafts. Because the high-traction wheel continues to rotate, the vehicle continues to move.

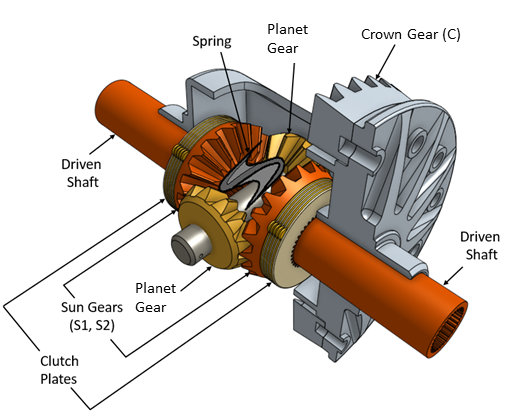

The figure shows the orientation of the major components in an LSD mechanism. The driveshaft pinion gear is not visible is this representation.

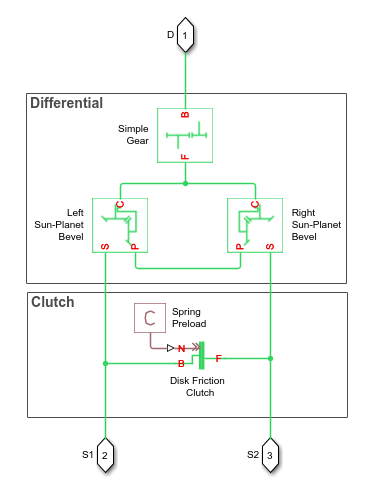

The Limited-Slip Differential block models the LSD mechanism as a structural component based on the Simscape™ Driveline™ Differential and Disc Friction Clutch blocks. The differential mechanism modeled by the Differential block is a structural component based on two other Simscape Driveline blocks, the Simple Gear and the Sun-Planet Bevel. The block diagram shows the structural components of the LSD.

The ports of the Limited-Slip Differential block are associated with the driveshaft (port D) and the two driven shafts (ports S1 and S2), which connect the sun gears to the wheels.

The Limited-Slip Differential block enables you to specify inertias only for the gear carrier and internal planet gears. By default, the inertias of the outer gears are assumed negligible. To model the inertias of the outer gears, connect Simscape Inertia blocks to the D, S1, and S2 ports.

The table shows the rotation direction of the driven shaft ports for different block parameterizations and input conditions.

| Rotation Direction of the Driven Shaft Ports (S1 and S2) | Crown Gear Location Relative to the Centerline | Rotation Direction of Driveshaft Port D | Relative Slippage Across the Differential |

|---|---|---|---|

| Positive | Right | Positive | 0 |

| Right | Positive | > 0 |

| Negative | Right | Negative | 0 |

| Right | Negative | > 0 |

| Negative | Left | Positive | 0 |

| Left | Positive | > 0 |

| Positive | Left | Negative | 0 |

| Left | Negative | > 0 |

Model

To examine the mathematical models for the structural components of the Limited-Slip Differential block, see:

Thermal Model

You can model

the effects of heat flow and temperature change by enabling the optional thermal port. To enable

the port, set Friction model to Temperature-dependent

efficiency.