Variable-Displacement Motor (TL)

Variable-displacement bidirectional thermal liquid motor

Libraries:

Simscape /

Fluids /

Thermal Liquid /

Pumps & Motors

Description

The Variable-Displacement Motor block represents a device that extracts power from a thermal liquid network and delivers it to a mechanical rotational network. The motor displacement varies during simulation according to the physical signal input specified at port D.

Ports A and B represent the motor inlets. Ports R and C represent the motor drive shaft and case. During normal operation, a pressure drop from port A to port B causes a positive flow rate from port A to port B and a positive rotation of the motor shaft relative to the motor case. This operation mode is referred to here as forward motor.

Operation Modes

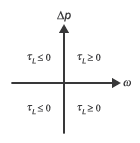

The block has eight modes of operation. The working mode depends on the pressure gain from port A to port B, Δp = pA – pB; the angular velocity, ω = ωR – ωC; and the fluid volumetric displacement at port D. The figure above maps these modes to the octants of a Δp-ω-D chart:

Mode 1, Forward Motor: Flow from port A to port B causes a pressure decrease from A to B and a positive shaft angular velocity.

Mode 2, Reverse Pump: Negative shaft angular velocity causes a pressure increase from port B to port A and flow from B to port A.

Mode 3, Reverse Motor: Flow from port B to port A causes a pressure decrease from B to A and a negative shaft angular velocity.

Mode 4, Forward Pump: Positive shaft angular velocity causes a pressure increase from port A to port B and flow from A to B.

Mode 5, Reverse Pump: Positive shaft angular velocity causes a pressure increase from port B to port A and flow from B to A.

Mode 6, Forward Motor: Flow from port A to port B causes a pressure decrease from A to B and a positive shaft angular velocity.

Mode 7, Forward Pump: Negative shaft angular velocity causes a pressure increase from port A to port B and flow from A to B.

Mode 8, Reverse Motor: Flow from B to A causes a pressure decrease from B to A and positive shaft angular velocity.

The response time of the motor is considered negligible in comparison with the system response time. The motor is assumed to reach steady state nearly instantaneously and is treated as a quasi-steady component.

Flow Rate and Driving Torque

The mass flow rate generated at the motor is

where:

is the actual mass flow rate.

is the ideal mass flow rate.

is the internal leakage mas flow rate.

The torque generated at the motor is

where:

τ is the actual torque.

τIdeal is the ideal torque.

τFriction is the friction torque.

The ideal mass flow rate is

and the ideal generated torque is

where:

ρ is the average of the fluid densities at thermal liquid ports A and B.

D is the displacement specified at physical signal port D.

ω is the shaft angular velocity.

Δp is the pressure drop from inlet to outlet.

Leakage and friction parameterization

You can parameterize leakage and friction analytically, using tabulated efficiencies or losses, or by input efficiencies or input losses.

When you set Leakage and friction parameterization to

Analytical leakage flow rate is

and the friction torque is

where:

KHP is the Hagen-Poiseuille coefficient for laminar pipe flows. This coefficient is computed from the specified nominal parameters.

μ is the dynamic viscosity of the thermal liquid, taken here as the average of its values at the thermal liquid ports.

k is the friction torque vs. pressure gain coefficient at nominal displacement, which is determined from the Mechanical efficiency at nominal conditions, ηm,nom:

τfr,nom is the friction torque at nominal conditions:

DNom is the specified value of the Nominal Displacement block parameter.

τ0 is the specified value of the No-load torque block parameter.

ωNom is the specified value of the Nominal shaft angular velocity block parameter.

ΔpNom is the specified value of the Nominal pressure drop block parameter. This is the pressure drop at which the nominal volumetric efficiency is specified.

The Hagen-Poiseuille coefficient is determined from nominal fluid and component parameters through the equation

where:

ωNom is the specified value of the Nominal shaft angular velocity parameter. This is the angular velocity at which the nominal volumetric efficiency is specified.

μNom is the specified value of the Nominal Dynamic viscosity block parameter. This is the dynamic viscosity at which the nominal volumetric efficiency is specified.

ηv,Nom is the specified value of the Volumetric efficiency at nominal conditions block parameter. This is the volumetric efficiency corresponding to the specified nominal conditions.

When you set Leakage and friction parameterization to

Tabulated data - volumetric and mechanical

efficiencies, the leakage flow rate is

and the friction torque is

where:

α is a numerical smoothing parameter for the motor-pump transition.

is the leakage flow rate in motor mode.

is the leakage flow rate in pump mode.

τFriction,Motor is the friction torque in motor mode.

τFriction,Pump is the friction torque in pump mode.

The smoothing parameter α is given by the hyperbolic tangent function

where:

ΔpThreshold is the specified value of the Pressure gain threshold for pump-motor transition block parameter.

ωThreshold is the specified value of the Angular velocity threshold for pump-motor transition block parameter.

DThreshold is the specified value of the Angular velocity threshold for motor-pump transition block parameter.

The leakage flow rate is calculated from the volumetric efficiency, a quantity that is specified in tabulated form over the Δp–ɷ–D domain via the Volumetric efficiency table block parameter. When operating in pump mode (octants 1 and 3 of the Δp–ɷ–D chart shown in the Operation Modes figure), the leakage flow rate is:

where ηv is the volumetric efficiency, obtained either by interpolation or extrapolation of the tabulated data. Similarly, when operating in motor mode (octants 2 and 4 of the Δp–ɷ–D chart), the leakage flow rate is:

The friction torque is similarly calculated from the mechanical efficiency, a quantity that is specified in tabulated form over the Δp–ɷ–D domain via the Mechanical efficiency table block parameter. When operating in pump mode (octants 1 and 3 of the Δp–ɷ–D chart):

where ηm is the mechanical efficiency, obtained either by interpolation or extrapolation of the tabulated data. Similarly, when operating in motor mode (octants 2 and 4 of the Δp–ɷ–D chart):

When you set Leakage and friction parameterization to

Tabulated data - volumetric and mechanical

losses, the leakage (volumetric) flow rate is specified directly

in tabulated form over the

Δp–ɷ–D

domain:

The mass flow rate due to leakage is calculated from the volumetric flow rate:

The friction torque is similarly specified in tabulated form:

where qLeak(Δp,ω,D) and τFriction(Δp,ω,D) are the volumetric and mechanical losses, obtained through interpolation or extrapolation of the tabulated data specified via the Volumetric loss table and Mechanical loss table block parameters.

When you set Leakage and friction parameterization to

Input signal - volumetric and mechanical

efficiencies, the leakage flow rate and friction torque

calculations are identical to the Tabulated data - volumetric and

mechanical efficiencies setting. The volumetric and mechanical

efficiency lookup tables are replaced with physical signal inputs that you

specify through ports EV and

EM.

The efficiencies are positive quantities with value between

0 and 1. Input values outside of these

bounds are set equal to the nearest bound (0 for inputs

smaller than 0, 1 for inputs greater than

1). The efficiency signals are saturated at the

Minimum volumetric efficiency or Minimum

mechanical efficiency and Maximum volumetric

efficiency or Maximum mechanical efficiency

.

When you set Leakage and friction parameterization to

Input signal - volumetric and mechanical

efficiencies, the leakage flow rate and friction torque

calculations are identical to the Tabulated data - volumetric and

mechanical efficiencies setting. The volumetric and

mechanical loss lookup tables are replaced with physical signal inputs that you

specify through ports LV and LM.

The block expects the inputs to be positive. It sets the signs automatically from the operating conditions established during simulation—more precisely, from the Δp–ɷ quadrant in which the component happens to be operating.

Energy Balance

Mechanical work done by the motor is associated with an energy exchange. The governing energy balance equation is:

where:

ΦA and ΦB are energy flow rates at ports A and B, respectively.

Phydro is a function of the pressure difference between motor ports: .

The motor mechanical power is generated due to torque, τ, and angular velocity, ω:

Assumptions

Fluid compressibility is negligible.

Loading on the motor shaft due to inertia, friction, and spring forces is negligible.