Segmented Pipeline

(To be removed) Hydraulic pipeline with resistive, fluid inertia, and fluid compressibility properties

The Hydraulics (Isothermal) library will be removed in a future release. Use the Isothermal Liquid library instead.

For more information on updating your models, see Upgrading Hydraulic Models to Use Isothermal Liquid Blocks.

Library

Pipelines

Description

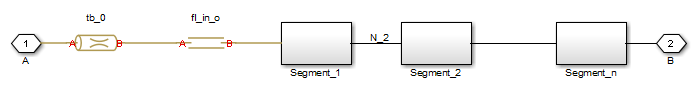

The Segmented Pipeline block models hydraulic pipelines with circular cross sections. Hydraulic pipelines, which are inherently distributed parameter elements, are represented with sets of identical, connected in series, lumped parameter segments. It is assumed that the larger the number of segments, the closer the lumped parameter model becomes to its distributed parameter counterpart. The equivalent circuit of a pipeline adopted in the block is shown below, along with the segment configuration.

Pipeline Equivalent Circuit

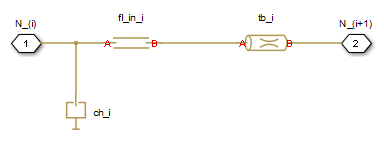

Segment Configuration

The model contains as many Constant Volume Hydraulic Chamber blocks as there are segments. The chamber lumps fluid volume equal to

where

V | Fluid volume |

d | Pipe diameter |

L | Pipe length |

N | Number of segments |

The Constant Volume Hydraulic

Chamber block is placed between two

branches, each consisting of a Hydraulic

Resistive Tube block and a Fluid

Inertia block. Every Hydraulic

Resistive Tube block lumps

(-th

portion of the pipe length, while Fluid Inertia

block has

L+L_ad)/(N+1)L/(N+1)L_ad denotes

additional pipe length equal to aggregate

equivalent length of pipe local resistances, such

as fitting, elbows, bends, and so on).

The nodes to which Constant Volume

Hydraulic Chamber blocks are connected are

assigned names N_1,

N_2, …,

N_

(nn is the number of

segments). Pressures at these nodes are assumed to

be equal to average pressure of the segment.

Intermediate nodes between Hydraulic

Resistive Tube and Fluid

Inertia blocks are assigned names

nn_0, nn_1,

nn_2, …,

nn_.

The Constant Volume Hydraulic

Chamber blocks are named

nch_1, ch_2,

…,

ch_,

Hydraulic Resistive Tube blocks are

named ntb_0,

tb_1, tb_2,

…,

tb_,

and Fluid Inertia blocks are named

nfl_in_0,

fl_in_1,

fl_in_2, …,

fl_in_.n

The number of segments determines the number of computational nodes associated with the block. A higher number increases model fidelity but decreases simulation speed. Experiment with different numbers to obtain a suitable trade-off between accuracy and speed. Use the following equation as a starting point in estimating a suitable number of segments:

where:

N | Number of segments |

L | Pipe length |

c | Speed of sound in the fluid |

| ω | Maximum frequency to be observed in the pipe response |

The table contains an example of simulation of a pipeline where the first four true eigenfrequencies are 89.1 Hz, 267 Hz, 446 Hz, and 624 Hz.

| Number of Segments | 1st Mode | 2nd Mode | 3rd Mode | 4th Mode |

|---|---|---|---|---|

| 1 | 112.3 | – | – | – |

| 2 | 107.2 | 271.8 | – | – |

| 4 | 97.7 | 284.4 | 432.9 | 689 |

| 8 | 93.2 | 271.9 | 435.5 | 628 |

The error between simulated and actual eigenfrequencies is less than 5% if an eight-segment model is used.

The flow rate through the pipeline is positive if it is directed from port A to port B. The pressure differential is positive if pressure is higher at port A than at port B.

Basic Assumptions and Limitations

Flow is assumed to be fully developed along the pipe length.

Parameters

- Pipe internal diameter

Internal diameter of the pipe. The default value is

0.01m.- Pipe length

Pipe geometrical length. The default value is

5m.- Number of segments

Number of lumped parameter segments in the pipeline model. The default value is

1.- Aggregate equivalent length of local resistances

This parameter represents total equivalent length of all local resistances associated with the pipe. You can account for the pressure loss caused by local resistances, such as bends, fittings, armature, inlet/outlet losses, and so on, by adding to the pipe geometrical length an aggregate equivalent length of all the local resistances. This length is added to the geometrical pipe length only for hydraulic resistance computation. Both the fluid volume and fluid inertia are determined based on pipe geometrical length only. The default value is

1m.- Internal surface roughness height

Roughness height on the pipe internal surface. The parameter is typically provided in data sheets or manufacturer’s catalogs. The default value is

1.5e-5m, which corresponds to drawn tubing.- Laminar flow upper margin

Specifies the Reynolds number at which the laminar flow regime is assumed to start converting into turbulent. Mathematically, this is the maximum Reynolds number at fully developed laminar flow. The default value is

2000.- Turbulent flow lower margin

Specifies the Reynolds number at which the turbulent flow regime is assumed to be fully developed. Mathematically, this is the minimum Reynolds number at turbulent flow. The default value is

4000.- Pipe wall type

The parameter can have one of two values:

Rigid WallorFlexible Wall. If the parameter is set toRigid Wall, wall compliance is not taken into account, which can improve computational efficiency. The valueFlexible Wallis recommended for hoses and metal pipes where wall compliance can affect the system behavior. The default value isRigid Wall.- Static pressure-diameter coefficient

Coefficient that establishes relationship between the pressure and the internal diameter at steady-state conditions. This coefficient can be determined analytically for cylindrical metal pipes or experimentally for hoses. The parameter is used if the Pipe wall type parameter is set to

Flexible Wall, and the default value is2e-10m/Pa.- Viscoelastic process time constant

Time constant in the transfer function that relates pipe internal diameter to pressure variations. By using this parameter, the simulated elastic or viscoelastic process is approximated with the first-order lag. The value is determined experimentally or provided by the manufacturer. The default value is

0.008s.- Specific heat ratio

Gas-specific heat ratio for the Constant Volume Hydraulic Chamber block. The default value is

1.4.- Initial pressures at model nodes

Lets you specify the initial condition for pressure inside the pipe segments. The parameter can have one of two values:

The same initial pressure for all nodes— The initial pressure in all pipe segments is the same, and is specified by the Initial pressure parameter value. This is the default.Custom— Lets you specify initial pressure individually for each pipe segment, by using the Initial pressure vector parameter. The vector size must be equal to the number of pipe segments, defined by the Number of segments parameter value.

- Initial pressure

Specifies the initial pressure in all pipe segments. The parameter is used if the Initial pressures at model nodes parameter is set to

The same initial pressure for all nodes, and the default value is0.- Initial pressure vector

Lets you specify initial pressure individually for each pipe segment. The parameter is used if the Initial pressures at model nodes parameter is set to

Custom. The vector size must be equal to the number of pipe segments, defined by the Number of segments parameter value.- Initial flow rate

Specifies the initial volumetric flow rate through the pipe. The default value is

0 m^3/s.

Global Parameters

Parameters determined by the type of working fluid:

Fluid density

Fluid kinematic viscosity

Use the Hydraulic Fluid block or the Custom Hydraulic Fluid block to specify the fluid properties.

Ports

The block has the following ports:

AHydraulic conserving port associated with the pipe inlet.

BHydraulic conserving port associated with the pipe outlet.