3-Zone Pipe (2P)

Pipe with phase-changing fluid in a two-phase fluid network

Libraries:

Simscape /

Fluids /

Two-Phase Fluid /

Pipes & Fittings

Description

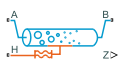

The 3-Zone Pipe (2P) block models a pipe with a phase-changing fluid. Each fluid phase is called a zone, which is a fractional value between 0 and 1. Zones do not mix. The block uses a boundary-following model to track the sub-cooled liquid (L), vapor-liquid mixture (M), and super-heated vapor (V) in three zones. The relative amount of space a zone occupies in the system is called a zone length fraction within the system.

Port H is a thermal port that represents the environmental temperature. The rate of heat transfer between the fluid and the environment depends on the fluid phase of each zone. The block models the pipe wall and the pipe wall temperature in each zone may be different. The fluid dynamic compressibility and the fluid zone thermal capacity impact the fluid pressure and temperature.

Heat Transfer Between the Fluid and the Wall

The convective heat transfer coefficient between the fluid and the wall, αF, varies per zone according to the Nusselt number

where:

Nuis the zone Nusselt number.k the average fluid thermal conductivity.

DH is the value of the Hydraulic diameter parameter, the equivalent diameter of a non-circular pipe.

The Nusselt number used in the heat transfer coefficient is the greater of the turbulent- and laminar-flow Nusselt numbers.

For turbulent flows in the subcooled liquid or superheated vapor zones, the Nusselt number is calculated with the Gnielinski correlation

where:

Reis the zone average Reynolds number.Pris the zone average Prandtl number.f is the Darcy friction factor, calculated from the Haaland correlation

where ε is the value of the Internal surface absolute roughnessparameter.

For turbulent flows in the liquid-vapor mixture zone, the Nusselt number is calculated with the Cavallini-Zecchin correlation

where:

ReSL is the Reynolds number of the saturated liquid.

PrSL is the Prandtl number of the saturated liquid.

ρSL is the density of the saturated liquid.

ρSV is the density of the saturated vapor.

a= 0.05, b = 0.8, and c= 0.33.

When fins are modeled on the pipe internal surface, the heat transfer coefficient is

where:

ηInt is the value of the Internal fin efficiency parameter.

sInt is the value of the Ratio of internal fins surface area to no-fin surface area parameter.

For laminar flows, the Nusselt number is the value of the Laminar flow Nusselt number parameter.

When the Heat transfer coefficient model parameter is Colburn equation, the block calculates the Nusselt number for the

subcooled liquid and superheated vapor zones by using the empirical

Colburn equation

where a, b, and c are values in the Coefficients [a, b, c] for a*Re^b*Pr^c in liquid zone and Coefficients [a, b, c] for a*Re^b*Pr^c in vapor zone parameters.

The block calculates the Nusselt number for liquid-vapor mixture zones by using the Cavallini-Zecchin equation with the variables in the Coefficients [a, b, c] for a*Re^b*Pr^c in mixture zone parameter.

The heat transfer rate from the fluid is based on the change in specific enthalpy in each zone

where is the mass flow rate for heat transfer. It is the pipe inlet mass flow rate, either A or B, depending on the direction of fluid flow.

In the liquid and vapor zones, the change in specific enthalpy is defined as

where:

cp is the specific heat of the liquid or vapor.

TH is the environmental temperature.

TI is the liquid inlet temperature.

z is the fluid zone length fraction.

αE is the heat transfer coefficient between the wall and the environment.

SW is wall surface area

where:

A is the value of the Cross-sectional area parameter.

L is the value of the Pipe length parameter.

The wall surface area does not include fin area, which is set by the Ratio of external fins surface area to no-fin surface area and Ratio of internal fins surface area to no-fin surface area parameters. Fins are set in proportion to the wall surface area. A value of

0means there are no fins on the pipe wall.

In the liquid-vapor mixture zone, the change in specific enthalpy is calculated as

where TS is the fluid saturation temperature. It is assumed that the liquid-vapor mixture is always at this temperature.

The total heat transfer between the fluid and the pipe wall is the sum of the heat transfer in each fluid phase

The heat transfer rate between the fluid and the pipe in the liquid zone is

where TW,L is the temperature of the wall surrounding the liquid zone.

The heat transfer rate between the fluid and the pipe in the mixture zone is

The heat transfer rate between the fluid and the pipe in the vapor zone is

where TW,V is the temperature of the wall surrounding the vapor zone.

Heat Transfer Between the Wall and the Environment

If the pipe wall has a finite thickness, the heat transfer coefficient between the wall and the environment, αE, is defined by

where αW is the heat transfer coefficient due to conduction through the wall

and where:

kW is the value of the Wall thermal conductivity parameter.

tW is the value of the Wall thickness parameter.

αExt is the value of the External environment heat transfer coefficient parameter.

ηExt is the value of the External fin efficiency parameter.

sExt is the value of the Ratio of external fins surface area to no-fin surface area parameter.

If the wall does not have thermal mass, the heat transfer coefficient between the wall and environment equals the heat transfer coefficient of the environment, αExt.

The heat transfer rate between each wall zone and the environment is

The total heat transfer between the wall and the environment is

The heat transfer rate depends on the thermal mass of the wall, CW

where:

cp,W is the value of the Wall specific heat parameter.

ρW is the value of the Wall density parameter.

The governing equations for heat transfer between the fluid and the external environment for the liquid zone are

for the mixture zone are

and for the vapor zone are

Momentum Balance

Two factors determine the pressure differential over the pipe: the changes in pressure due to changes in density, and changes in pressure due to friction at the pipe walls.

For turbulent flows, when the Reynolds number is above the value of the Turbulent flow lower Reynolds number limit parameter, the block calculates the pressure loss in terms of the Darcy friction factor. The pressure differential between port A and the internal node I is

where:

ρI is the fluid density at internal node I.

ρA* is the fluid density at port A, which is the same as ρA when the flow is steady-state. When the flow is transient, the block calculates ρA* from the fluid internal state at the internal node I with the adiabatic expression

where:

h is the average specific enthalpy,

ρ is the average density,

A is the mass flow rate through port A.

L is the value of the Pipe length parameter.

LAdd is the value of the Aggregate equivalent length of local resistances parameter, which is the equivalent length of a tube that introduces the same amount of loss as the sum of the losses due to other local resistances.

is the hydrostatic pressure, where:

M is the total fluid mass in the pipe.

V is the total fluid volume which is the volume of the pipe.

g is the value of the Gravitational acceleration parameter.

Δz is the value of the Elevation gain from port A to port B parameter.

The Darcy friction factor depends on the Reynolds number, which the block calculates at both ports.

The pressure differential between port B and internal node I is

where:

ρB* is the fluid density at port B, which is the same as ρB when the flow is steady-state. When the flow is transient, the block calculates ρB* from the fluid internal state with the adiabatic expression

B is the mass flow rate through port B.

For laminar flows, when the Reynolds number is below the value of the Laminar flow upper Reynolds number limit parameter, the block calculates the pressure loss due to friction in terms of the Laminar friction constant for Darcy friction factor parameter, λ. The pressure differential between port A and internal node I is

where μ is the average fluid dynamic viscosity

The pressure differential between port B and internal node I is

For transitional flows, the block smooths the pressure differential due to viscous friction between the values for laminar and turbulent pressure losses.

Mass Balance

The total mass accumulation rate is

In terms of the fluid zones, the mass accumulation rate is a function of the change in density, ρ, with respect to pressure, p, and the fluid specific internal energy, u

where uout is the specific internal energy after all heat transfer has occurred.

Energy Balance

The energy conservation equation is

where:

ϕA is the energy flow rate at port A.

ϕB is the energy flow rate at port B.

QF is the heat transfer rate between the fluid and the wall.

Assumptions and Limitations

The pipe wall is perfectly rigid.

The flow is fully developed. Friction losses and heat transfer do not include entrance effects.

Fluid inertia is negligible.

The block models gravitational effects at a bulk-system level and does not model the separation of liquid and vapor within the pipe due to gravity.

When the pressure is above the fluid critical pressure, large values of thermal fluid properties (such as Prandtl number, thermal conductivity, and specific heat) may not accurately reflect the heat exchange in the pipe.

Examples

Ports

Output

Conserving

Parameters

References

[1] White, F.M., Fluid Mechanics, 7th Ed, Section 6.8. McGraw-Hill, 2011.

[2] Çengel, Y.A., Heat and Mass Transfer—A Practical Approach, 3rd Ed, Section 8.5. McGraw-Hill, 2007.