SI Engine Torque Structure Model

The spark-ignition (SI) engine implements a simplified version of the SI engine torque structure calculation used in a Bosch Engine Management System (EMS). For the torque structure estimation calculation, the block requires calibration tables for:

Inner torque — Maximum torque potential of the engine at a given speed and load

Friction torque — Torque losses due to friction

Optimal spark — Spark advance for optimal inner torque

Spark efficiency — Torque loss due to spark retard from optimal

Lambda efficiency — Torque loss due to lambda change from optimal

Pumping torque — Torque loss due to pumping

The tables available with Powertrain Blockset™ were developed with the Model-Based Calibration Toolbox™.

| Lookup Table | Used to Determine | Plot |

|---|---|---|

|

Inner torque, |

|

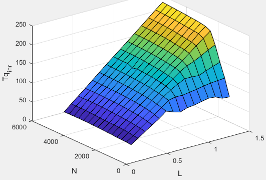

The inner torque lookup table, , is a function of engine speed and engine load, , where:

|

|

Friction torque, |

|

The friction torque lookup table, , is a function of engine speed and engine load, , where:

|

|

Pumping torque, ƒTpump |

|

The pumping torque lookup

table, ƒTpump, is a function of engine load and engine

speed,

|

|

Optimal spark, |

|

The optimal spark lookup table, , is a function of engine speed and engine load, , where:

|

|

Spark efficiency, |

|

The spark efficiency lookup table, , is a function of the spark retard from optimal where:

|

|

Lambda efficiency, |

|

The lambda efficiency lookup table, , is a function of lambda, , where:

|

The engine brake torque is a based on inner torque with lambda efficiency, spark retard efficiency multipliers, pumping torque, and a friction torque offset

To account for thermal effects, the torque structure model corrects the friction torque calculation as a function of coolant temperature.

The pumping torque is a function of engine speed and engine speed.

|

Optimal spark advance timing for maximum inner torque at stoichiometric air-fuel ratio (AFR) | |

|

Spark retard timing distance from optimal spark advance | |

|

Spark advance timing | |

|

Engine load at arbitrary cam phaser angles, corrected for final steady-state cam phaser angles | |

| N |

Engine speed |

|

Lambda multiplier on inner torque to account for the AFR effect | |

|

Lambda, AFR normalized to stoichiometric fuel AFR | |

|

Spark retard efficiency multiplier | |

|

Spark efficiency lookup table to account for torque loss due to spark retard from optimal | |

|

Friction torque lookup table to account for torque losses due to friction | |

|

Lambda efficiency lookup table to account for torque loss due to lambda change from optimal | |

|

Optimal spark lookup table, for maximum inner torque as a function of engine speed and load | |

|

Inner torque lookup table, for maximum torque potential of the engine at a given speed and load | |

|

Engine brake torque after accounting for spark advance, AFR, and friction effects | |

|

Friction torque offset to inner torque | |

|

Inner torque based on gross indicated mean effective pressure | |

| Tpump |

Pumping torque |

| Mfric |

Friction torque modifier |

| Tcoolant |

Coolant temperature |

References

[1] Gerhardt, J., Hönninger, H., and Bischof, H., A New Approach to Functional and Software Structure for Engine Management Systems – BOSCH ME7. SAE Technical Paper 980801, 1998.

See Also

SI Controller | SI Core Engine