Pipe Flow with Entrained Water Droplets

This example shows how to model water droplets that are entrained in a moist air flow. When water vapor condenses in a moist air block, the condensate can become entrained in the moist air flow as small suspended water droplets or ice crystals. In real world systems this can appear as fog. The moist air blocks assume the droplets are small aerosol particles, and take up negligible space. Thus water droplets do not contribute to the specific volume or density of the moist air flow. Furthermore, water droplets are assumed not to affect moist air transport properties such as dynamic viscosity and thermal conductivity. However, water droplets do contribute to the enthalpy and thermal mass of the moist air flow and can therefore affect the temperature variation of the flow. In addition, water droplets can evaporate back into the moist air flow downstream when the relative humidity drops back below saturation. The latent heat for re-evaporation is absorbed from the moist air flow which lowers the moist air temperature.

In the Moist Air Properties (MA) block, select the Enable entrained water droplets parameter to enable the connected moist air network to track water droplets as they are convected by the flow through the network. In moist air blocks where condensation may occur, such as the Pipe (MA) block and the Constant Volume Chamber (MA) block, the Fraction of condensate entrained as water droplets parameter determines how much of the condensation remains in the moist air flow as suspended water droplets. The remaining amount of condensation is assumed to leave the moist air flow.

This model consists of two Pipe (MA) blocks in series. The wall temperature of both pipes drop by 15 K, resulting in condensation. Because the Fraction of condensate entrained as water droplets parameter is set to one, all of the condensate remains in the flow as water droplets. The wall temperature of the second pipe then rises by 15 K. The heating causes some of the water droplets to evaporate back into water vapor. Due to the latent heat of the evaporated water droplets, the temperature of the second pipe does not rise as much as it would if there were no water droplets. Finally, the Moisture Separator (MA) block removes any remaining water droplets from the moist air flow.

Model

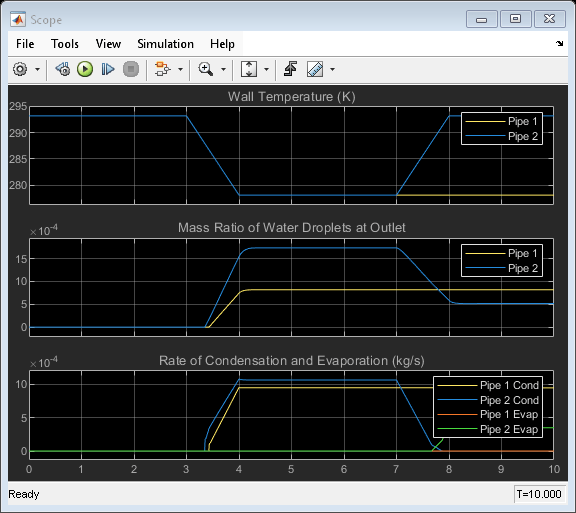

Simulation Results from Scopes

Simulation Results from Simscape Logging

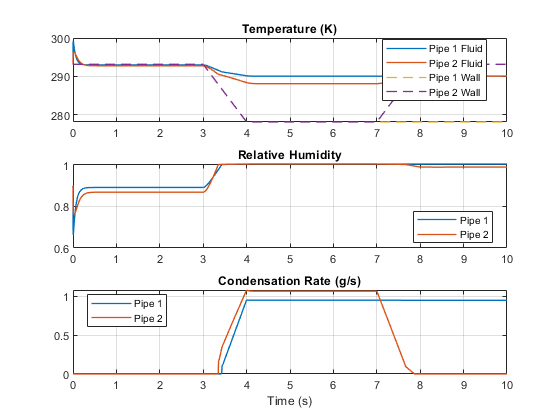

The following figure shows the condensation that occurs when the wall temperature of the two pipes drops by 15 K at t = 3 s. As the moist air temperature drops, the relative humidity increases to 100%. Water vapor then condenses at a rate of 0.951 g/s for the first pipe in order to keep the amount of water vapor from going above saturation. Because the moist air temperature of the second pipe drops further, it has a greater rate of condensation at 1.06 g/s. At t = 7 s, the wall temperature of the second pipe rises by 15 K and condensation stops.

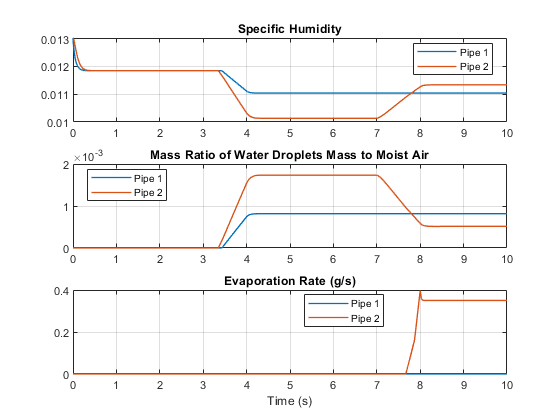

The following figure shows the water droplets that are entrained by the moist air flow due to the condensation shown in the previous figure. At t = 3 s, the specific humidity (water vapor mass fraction) falls at the same time that the mass ratio of water droplets to moist air increases. At t = 7, the increase in wall temperature of the second pipe lowers the relative humidity, which allows some of the water droplets to evaporate back into the moist air flow.

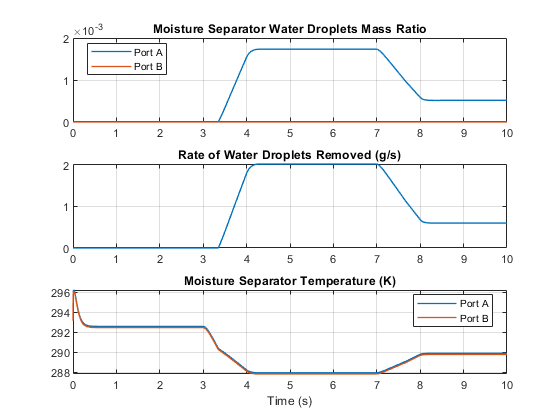

The Moisture Separator (MA) block is a simplified component that removes a specified portion of water vapor and/or water droplets from the flow. In this model, the block removes all remaining water droplets downstream of the second pipe. The following figure shows the amount of water droplets at port A (inlet) and port B (outlet) of the moisture separator. The mass ratio of water droplets is zero at port B, as expected. The block is assumed to remove moisture mechanically, not thermodynamically. Therefore, the temperature is unchanged between port A and port B.